How To Remove Rusted Shock Bolts

A rusted, seized bolt or nut tin plough an easy project into a nightmare.

In fact, mechanics have been known to hold a lucky rabbit's foot or turn down to work on Friday the thirteenth for that very reason.

Merely removing a stuck commodities doesn't rely on luck—it relies on the proper preparation and tools.

OnAllCylinders contributor Jim Smart wrote an in-depth article that covers a lot of the stuff nosotros mention here, but goes deeper into the topic of thread repair. Yous can bank check it out here: Taking The Sting Out of Damaged Threads

Program Ahead.

If you have the luxury of planning a bolt removal in advance, then accept advantage of your head start past spraying the bolt with penetrating oil.

A quality penetrating oil does two things:

It volition human activity every bit a mild solvent to consume away at rust, plus it will lubricate the threads, which volition brand for an easier extraction (and mitigate the take chances of snapping a bolt due to corroded threads.)

Some folks will make their ain blend of penetrants using mutual garage substances similar automatic manual fluid, acetone, and candle wax—but we're inclined to trust the off-the-shelf stuff.

Start several days in advance, spraying the bolt or nut every day with a fresh blast of penetrant.

Don't exist stingy—really soak the nut or bolt down. Allow the penetrating oil a good chance to pitter-patter in to the bolt threads.

If the commodities or nut is located in a tight space, attempt to remove as many obstacles (brackets, panels, etc.) every bit yous can to ensure your socket and wrench/breaker bar has enough room to seat and plough properly on the fastener's head.

Use the Right Tools.

When information technology comes time to remove the bolt, take your 12-indicate socket and hide it in your sock drawer adjacent to your four-leaf clover—y'all won't need either one.

Utilize a half-dozen-signal socket for a traditional hex-head commodities. That will reduce the chance of accidentally rounding the caput or nut.

If your bolt in question is an Allen or Torx, brand admittedly-positively sure yous've got the right-size fleck. (AMC and Jeep folks know what we're talking most.)

Take a wire brush and knock-off whatsoever corrosion on the bolt head. You want to ensure your socket is seated fully onto the fastener.

Don't lead off with an impact wrench or breaker bar. Instead, try to see if yous can break the commodities free with your trusty socket wrench. You don't want to risk shearing the commodities caput off with unnecessary force.

Greek History Time!

If, after all that, your bolt is stuck—call Archimedes.

Archimedes was an aboriginal Greek gearhead who was the first to mathematically explain the mechanical reward of a long lever. In other words, he helped invent the breaker bar. Applying gentle force, utilize the bar's leverage to utilize more than turning strength to the bolt head. Feel is important, and if you recollect y'all're going to round or shear the bolt caput, back off the fastener.

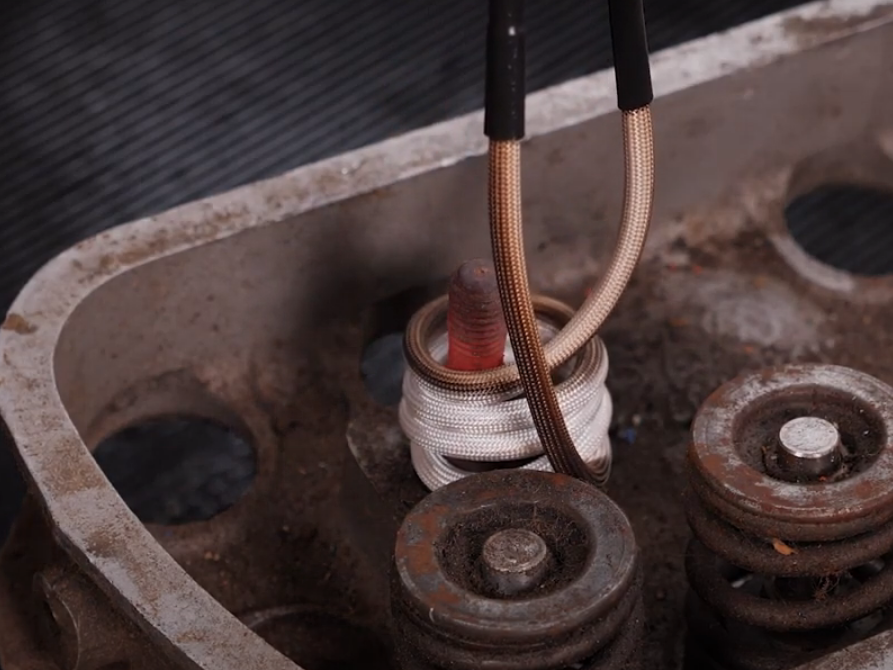

If a billow bar nonetheless won't release the bolt, information technology'southward time to contact Prometheus.

In Greek mythology, Prometheus stole fire from the gods and gave it to the mortals. Now, thanks to him, you can apply that fire to united nations-stuck your bolt.

Using a torch, rut the bolt caput or nut. Due to thermal dynamics, the bolt or nut volition aggrandize. The promise is that expansion and contraction process will likewise un-seize the commodities, breaking the corrosion that grips the threads.

Obviously, you'll want to accept great care to avoid any damage acquired by the intense oestrus. Clear away any solvents, and brand sure you're not using your torch near a fuel line and oil-weeping gasket. Your torch will also quickly melt plastic and rubber, so exist mindful of bushings, mounts, and boots. (Mini torches and induction tools are really handy for this sort of task.)

Keep the heat centered precisely on the bolt head or nut for virtually 20-30 seconds, and and so let it cool.

Though opinions differ, nosotros recommend waiting for the fastener to cool dorsum down before you lot attempt to turn it. Again, the magic of this method occurs in the expansion action breaking loose the corrosion.

Impact Play.

An electric or air-powered touch on wrench is the stuck bolt'southward arch nemesis. If y'all're lucky enough to have one, remember to try to loosen the bolt by hand offset—as well much torque too fast tin spell disaster to a rusted fastener.

In add-on to the rotation force of the wrench, the bear upon action volition help shock the bolt gratuitous, loosening corrosion that may exist gripping the bolt.

Preventative Maintenance.

In that location are several things you can do to help prevent the bolt getting stuck in the first place.

- Proper Torque. Avert over-tightening bolts.

- Thread Lubricant/Anti-Seize. Utilise a quality thread lubricant to the bolt or stud to forestall seizing caused by galvanic corrosion.

- Paint the Fastener Heads. A simple coat of spray pigment will go on rust and corrosion off the fastener caput, and foreclose moisture from creeping into the threads.

- Castor Up. Don't be shy about occasionally using a wirecastor on the fastener head. It will go on muck and moisture out of the threads.

- Add a Coat of Grease or Oil. If you're unable to paint the heads, so periodically spraying them downward with a penetrating oil or applying a pocket-size dollop of grease will work merely also. It's also smart to do the same thing to the bolt's threads, if they're exposed backside a bracket.

A Lucky Plow?

Hopefully, following these tips has been helpful, and your bolt or nut is lying harmlessly on the cement in front of you.

If information technology isn't, and you've rounded your fastener head or sheared it off completely, don't despair.

There are products out at that place to remedy a rounded nut and extract a broken stud—and none of them involve knocking on forest, wishing on rainbows, or crossing your fingers.

Source: https://www.onallcylinders.com/2017/10/13/how-to-remove-rusted-bolts-and-loosen-stuck-seized-or-frozen-nuts-and-bolts/

0 Response to "How To Remove Rusted Shock Bolts"

Post a Comment